Saturn Machine Works values its customers. We take pride in providing excellent service, workmanship, quality and on-time delivery.

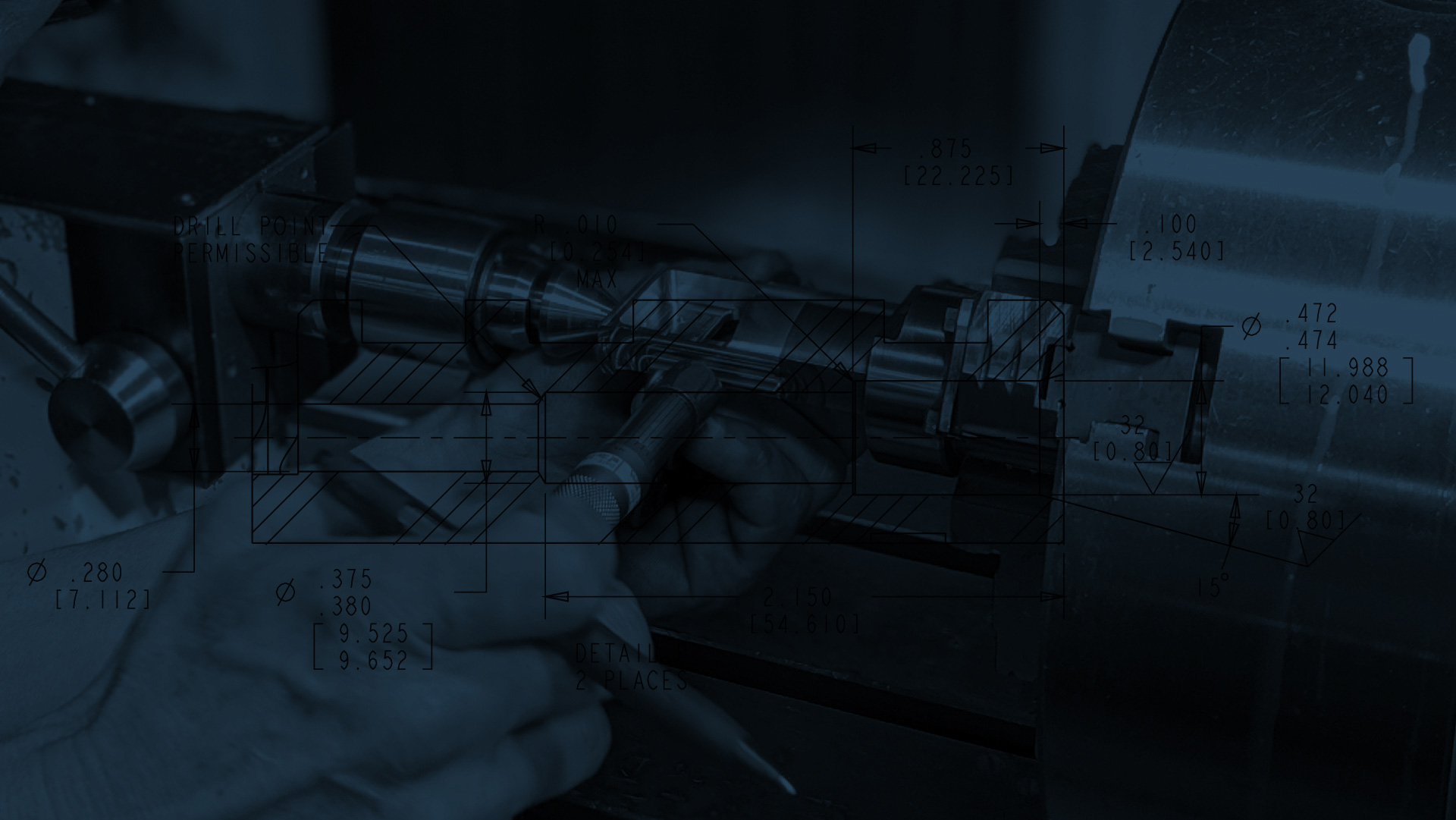

At Saturn Machine Works, we provide standard machining, along with custom machining capabilities. We provide high-performance, custom design solutions, and machine high quality, complex parts at a competitive cost. We work directly with customers to solve specific challenges, and to find solutions for difficult machining processes. Whether you need an R&D prototype, or a full production run, our team of in-house CNC machinists can get the job done.

Saturn Machine Works remains dedicated to consistently delivering top-tier products that not only meet, but surpass customer expectations. Our quality system mirrors ISO 9001:2015, ensuring complete traceability. Click here for our quality model. A quality manual is available on request.